Miniature ball bearings are small, high-precision components that play a crucial role in a wide range of compact mechanical applications. This article explores the key features and benefits of miniature ball bearings, including their construction, functionality, and significance in providing smooth and efficient rotational motion. By understanding the advantages of miniature ball bearings, engineers and designers can make informed decisions when selecting and integrating these components into their miniature systems.

Construction and Design

Miniature ball bearings are designed with specific features to accommodate the requirements of compact applications.

Small Size:

Miniature ball bearings are characterized by their small outer diameter, bore diameter, and width. They are available in various size ranges, often measured in millimeters, making them suitable for space-constrained applications.

High Precision:

These bearings are engineered with precision in mind, featuring tight tolerances and meticulous manufacturing processes. This precision ensures minimal friction, smooth operation, and high rotational accuracy.

Advantages and Benefits

Miniature ball bearings offer several advantages over other bearing types, making them indispensable components in many miniature applications.

Reduced Friction and Energy Loss:

Miniature ball bearings utilize rolling elements (balls) that reduce friction compared to sliding contact bearings. This leads to lower energy consumption and improved overall efficiency.

High-Speed Capability:

Due to their precise construction and low friction, miniature ball bearings can operate at high speeds, enabling fast and efficient rotational motion in compact systems.

Radial and Axial Load Support:

Despite their small size, miniature ball bearings are designed to handle both radial and axial loads. This versatility allows them to support different types of loads in various miniature applications.

Noise and Vibration Reduction:

Miniature ball bearings contribute to smooth and quiet operation by minimizing noise and vibration. This is particularly important in sensitive applications where noise reduction and smooth motion are essential.

Applications and Considerations

Miniature ball bearings find application in a wide range of industries and products that require compact, precise, and reliable rotational motion.

Robotics and Automation:

Miniature ball bearings are widely used in robotics and automation systems, where they provide smooth motion control for precision movements and robotic arm joints.

Medical and Dental Equipment:

These bearings are critical components in medical and dental equipment, such as surgical instruments, dental handpieces, and imaging devices. They ensure precise and reliable operation in these delicate and sensitive applications.

Aerospace and Aviation:

In the aerospace and aviation industries, miniature ball bearings are utilized in navigation systems, control mechanisms, and miniature components in aircraft and spacecraft.

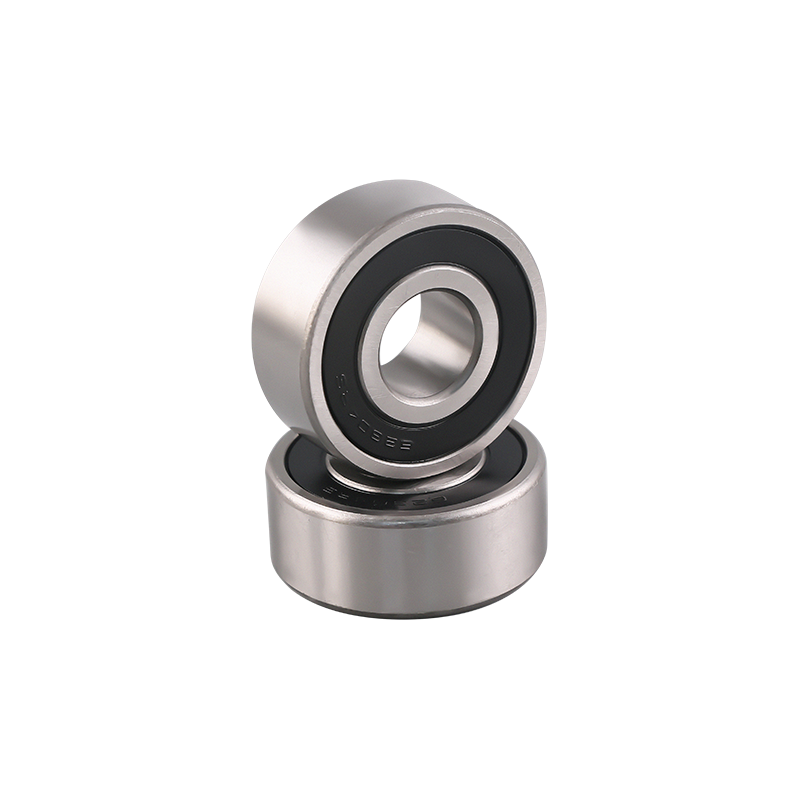

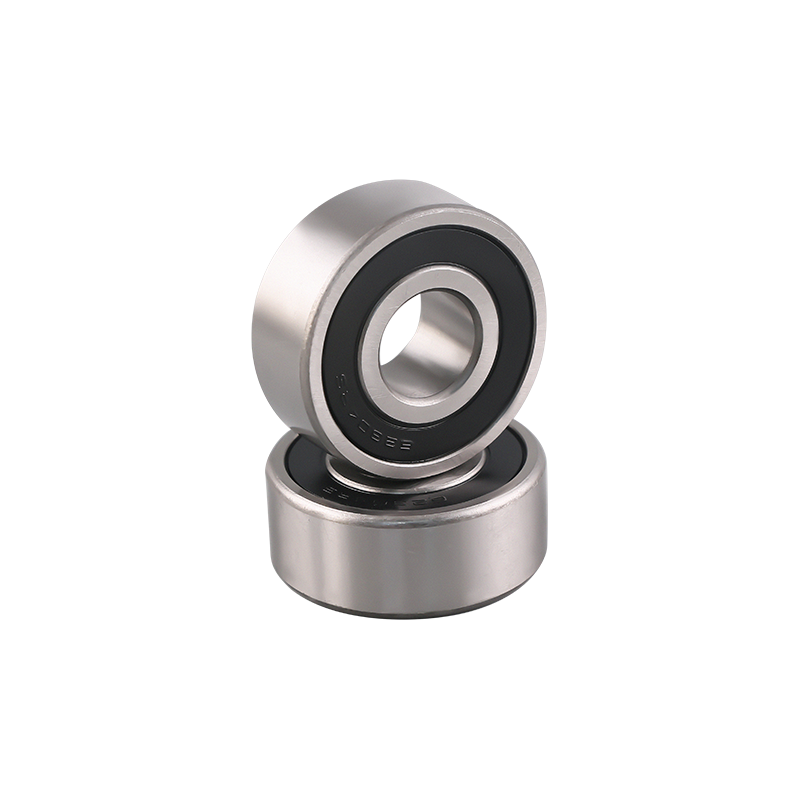

Single-row deep groove ball bearings are the most common type of rolling bearing. The raceway grooves in the inner and outer rings form a circular arc cross-section with a slightly larger radius than that of the rolling balls.

In addition to open varieties, these bearings can have steel shields or come pre-lubricated with grease maintained by rubber seals installed on one or both sides. Snap rings are sometimes used on the outside diameter of the outer ring.