We know that

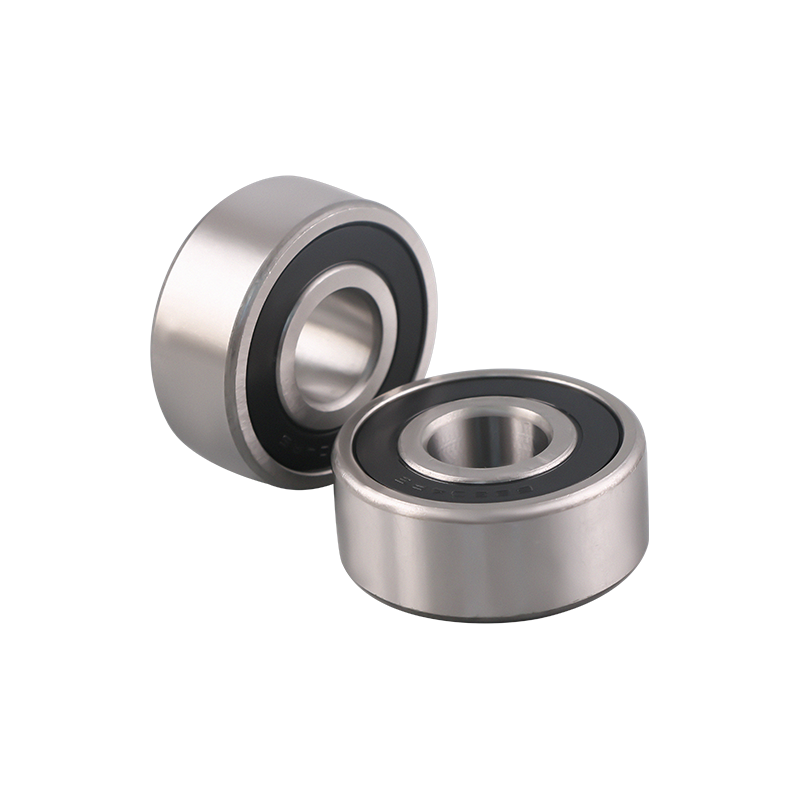

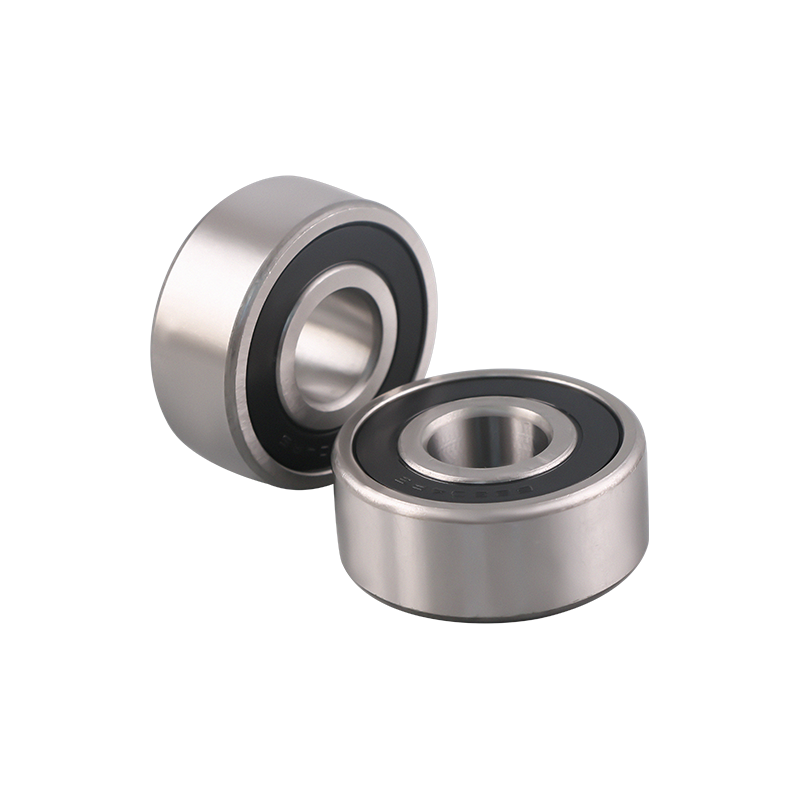

bearings play a big role in our daily life, and the appearance of stainless steel bearings is used in various fields. However, there are also ways to install stainless steel bearings, which cannot be installed at will. The following editor will explain in detail the precautions for stainless steel bearing installation.

1. To lubricate and clean

Before installing stainless steel bearings, we need to clean the bearing surface, and then we need to disassemble and inspect the surrounding parts of the bearing. After there is no problem with the bearing, it is also necessary to check the problem of its lubrication. When checking and lubricating, select the relevant person to carry out, and can not disassemble at will.

2. Lubricant quality

Generally, many friends find that the life of stainless steel bearings is too short, and the reason is caused by the use of lubricants. The use of poorer quality lubricants naturally forces a reduction in bearing life. Checking the quality of the lubricant is simple. Apply a little lubricant with your hands, and then rub with two fingers. If you find that there is particulate contamination, then it is not good.

3. Pay attention to the working environment

When we use stainless steel bearings, remember not to let them work in contaminants or in wet environments. When the work is interrupted, the machine should be covered with materials such as oil paper and plastic sheets. A good working environment can increase the service life of stainless steel bearings, but if you think about it, it will reduce its service life.

The precautions for stainless steel bearing installation are introduced here first. I believe that friends will have a general understanding after reading this article. In fact, to put it simply, when we install the bearing, we must consider these problems, which is also the main basis for the normal operation of the bearing.