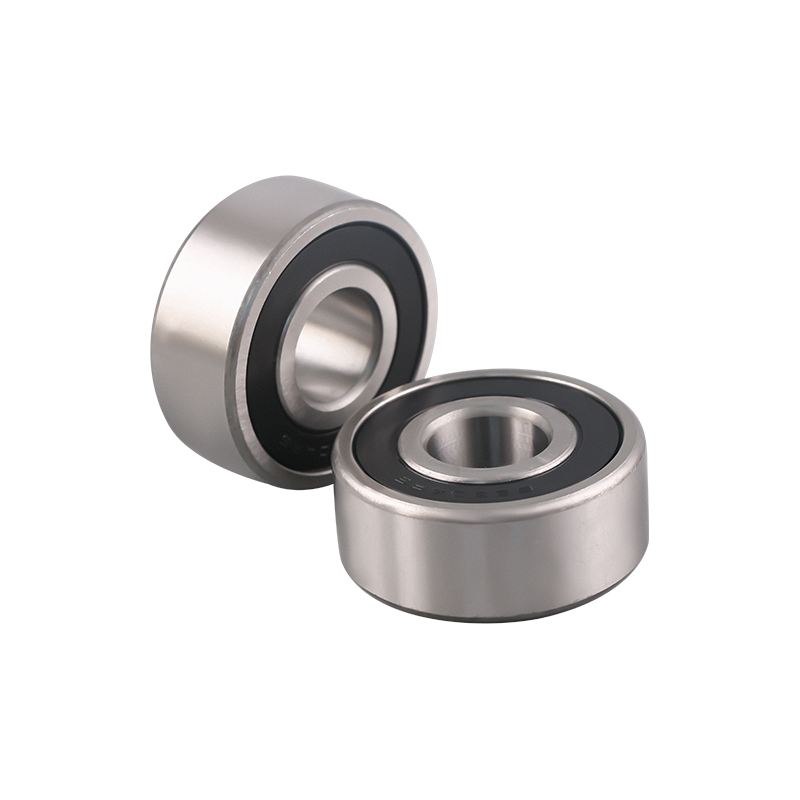

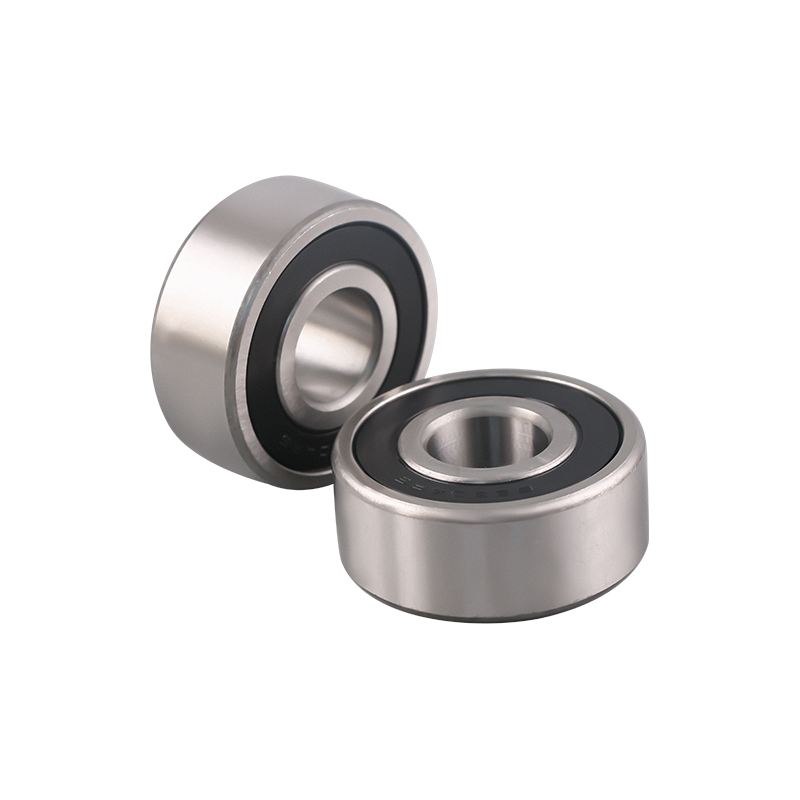

The inner ring and outer ring of the deep groove ball bearing are selected with appropriate materials, and the steel ball is the key, because it has a significant impact on the performance of the deep groove ball bearing.

The contact area between the outer ring and the inner ring and the ball is seriously over 1000MPa and high stress is repeatedly applied. The type of material, purity, hardness are very important factors because of long life even under high stress repeated application.

High carbon chromium bearing steel and high corrosion resistance martensitic stainless steel raceways and balls are used on our products.

High carbon chromium bearing steel raceways and balls are made of high quality vacuum degassed high carbon chromium steel or equivalent. With proper heat treatment, they have strong load resistance, longer life and low noise performance.