The basic structure of the rolling

bearingThe working principle of rolling bearing is to replace sliding friction with rolling friction, and its structure is generally a mechanical base composed of two rings, a set of rolling elements, and a cage. Due to the different working conditions of rolling bearings, there are different requirements for the structure, load capacity, and performance of bearings, so rolling bearings also have various structures. However, the most basic structure of rolling bearings is composed of an inner ring, outer ring, rolling elements, and cage.

The role of each structural part of the bearing:

The inner ring of the radial bearing usually fits tightly with the shaft and runs together with the shaft, and the outer ring forms a transition fit with the bearing seat or the hole of the mechanical housing to play a supporting role. In some cases, the radial bearing also has an outer ring running, and the inner ring is fixed to play a supporting role, or both the inner ring and the outer ring are running at the same time. The thrust bearing is called a shaft washer that is tightly fitted with the shaft and moves together and is called a seat washer that is in transition fit with the bearing seat or the hole of the mechanical housing and plays a supporting role. The rolling elements (steel balls, rollers, or needles) are usually evenly arranged in the bearing between the two rings for rolling motion by means of a cage. Its shape, size, and quantity directly affect the load capacity and performance of the bearing. In addition to evenly separating the rolling elements, the cage can also guide the rolling elements to rotate and improve the internal lubrication performance of the bearing.

Classification of rolling bearings

1. Classification by rolling bearing structure type

(1) Bearings are classified into:

Radial bearing---- mainly used for rolling bearing radial load, its nominal contact angle is from 0 to 45. The different nominal contact angles, it is divided into radial contact bearings - radial bearings with a nominal contact angle of 0; radial angular contact bearings - radial bearings with a nominal contact angle greater than 0 to 45.

Thrust bearing ---- mainly used for rolling bearing axial load, its nominal contact angle is greater than 45 to 90. According to the different nominal contact angles, it is divided into Axial contact bearings----thrust bearings with a nominal contact angle of 90: thrust angular contact bearings----thrust bearings with a nominal contact angle greater than 45 but less than 90.

(2) Bearings are divided into:

Ball bearing - the rolling element is a ball:

Roller bearings----The rolling elements are rollers. According to the type of rollers, roller bearings are divided into Cylindrical roller bearings----the rolling elements are cylindrical roller bearings, and the ratio of the length to the diameter of the cylindrical rollers is less than or equal to 3; needle roller bearings---- The rolling element is a needle roller bearing, the ratio of the length to the diameter of the needle roller is greater than 3, but the diameter is less than or equal to 5mm; tapered roller bearing----the rolling element is a tapered roller bearing; spherical roller bearing one by one The rolling elements are spherical roller bearings.

(3) Bearings are divided into:

Self-aligning bearing—the raceway is spherical, which can adapt to the angular deviation and angular motion between the axis lines of the two raceways;

Non-aligning bearings (rigid bearings) ---- bearings that can resist the angular deviation of the axis line between the raceways.

(4) Bearings are divided into:

Single-row bearings—bearings with one row of rolling elements;

Double-row bearings—bearings with two rows of rolling elements;

Multi-row bearings—bearings with more than two rows of rolling elements, such as three-row and four-row bearings.

(5) Bearings are divided into:

Separable bearings—bearings with separable parts;

Non-separable bearings—bearings in which the rings cannot be freely separated after the bearing is finally matched.

(6) Bearings can also be divided into various structural types according to their structural shapes (if there is no filling groove, whether there are inner and outer rings and the shape of the ferrule, the structure of the rib, and even whether there is a cage, etc.).

2. Classification according to the size of rolling bearings Bearings are divided into:

(1) Miniature bearings - bearings with a nominal outer diameter range of less than 26mm;

(2) Small bearings - bearings with a nominal outer diameter range of 28-55mm;

(3) Small and medium-sized bearings—bearings with a nominal outer diameter range of 60-115mm;

(4) Medium and large bearings - bearings with a nominal outer diameter range of 120-190mm

(5) Large bearings - bearings with a nominal outer diameter range of 200-430mm;

(6) Extra-large bearing—bearings with a nominal outer diameter range of 440mm or more.

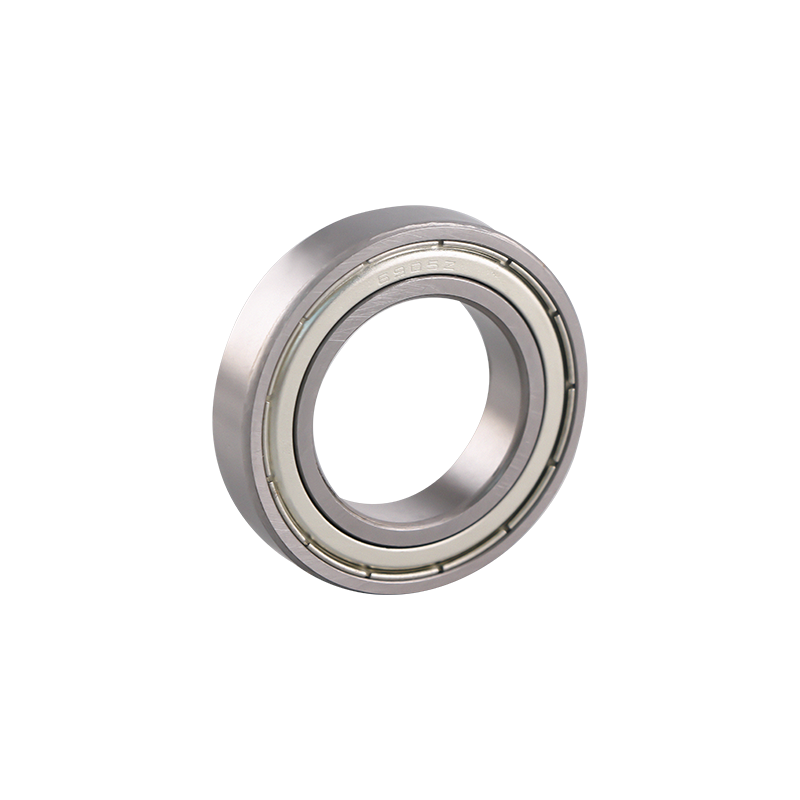

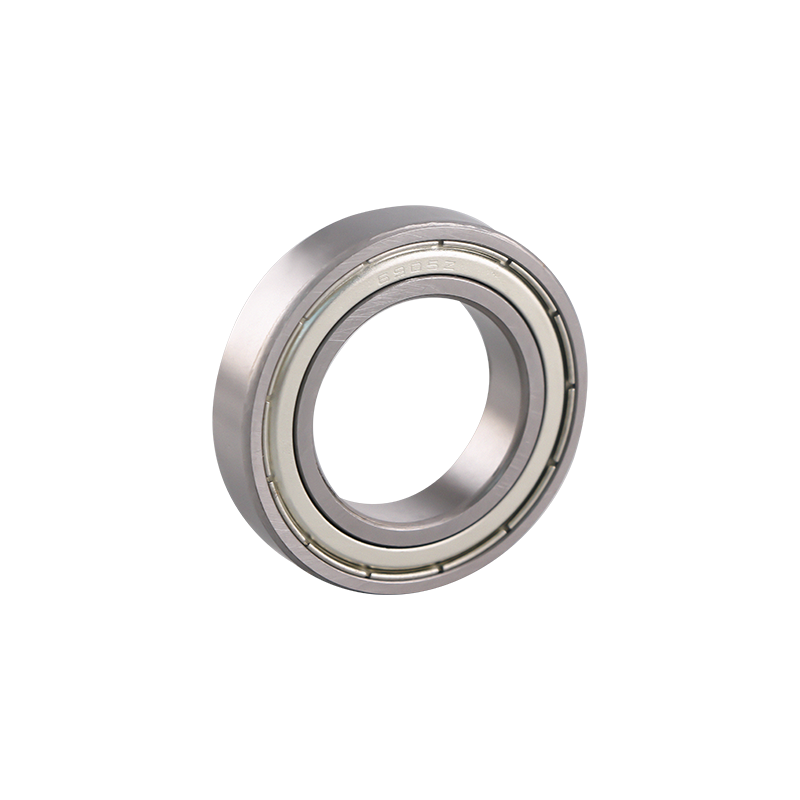

6906 ZZ/2RS Open 30x47x9mm Thin Wall Bearing Robot Spherical Plain Bearing Deep Groove Ball Bearing

We are an international custom 6906 ZZ/2RS Open 30x47x9mm Thin Wall Bearing Robot Spherical Plain Bearing Deep Groove Ball Bearing suppliers and OEM/ODM 6906 ZZ/2RS Open 30x47x9mm Thin Wall Bearing Robot Spherical Plain Bearing Deep Groove Ball Bearing company, specialized in the manufacturing deep groove ball bearing. Not only advanced automated production equipment, strict enterprise management, excellent talent team, and strong technology, rigorous process, but also we have a large number of precision grinding machine, mainly use high-quality bearing steel "GCr15" as raw material, and low-carbon alloy steel as attached. The first inspection, Operator self-inspection, inspect all the sizes; Inspect sampling, factory finished product testing and other processes, custom 6906 ZZ/2RS Open 30x47x9mm Thin Wall Bearing Robot Spherical Plain Bearing Deep Groove Ball Bearing quality has been Strict controlled. Our quality goal is the pursuit of excellence, achieve customer satisfaction.